Monomaterials: The Future of Flexible Packaging Sustainability

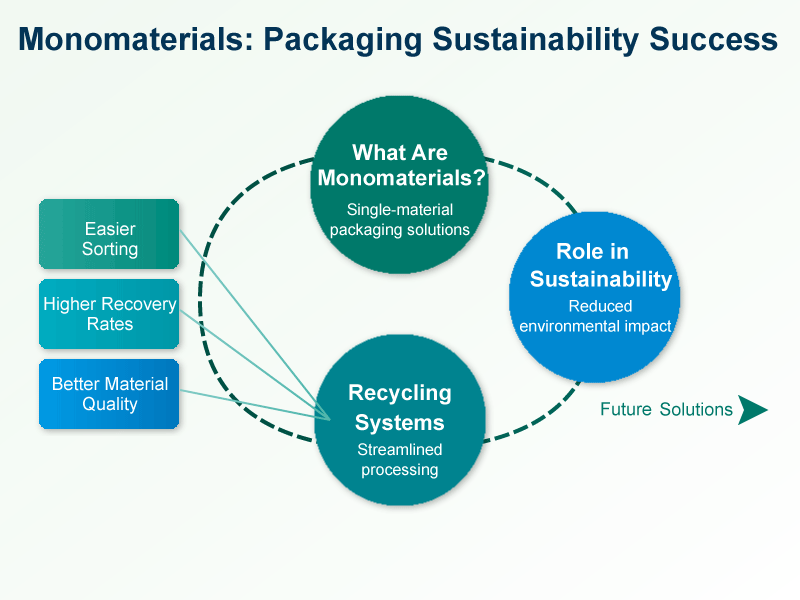

Sustainability in packaging is no longer a mere trend; it is becoming a necessity driven by environmental concerns and regulatory demands. Among the most promising advancements in this realm are monomaterials, single-material compositions that offer a host of benefits over traditional multilayered packaging. For packaging engineers, understanding the potential of monomaterials is crucial for developing future-ready solutions.

What Are Monomaterials?

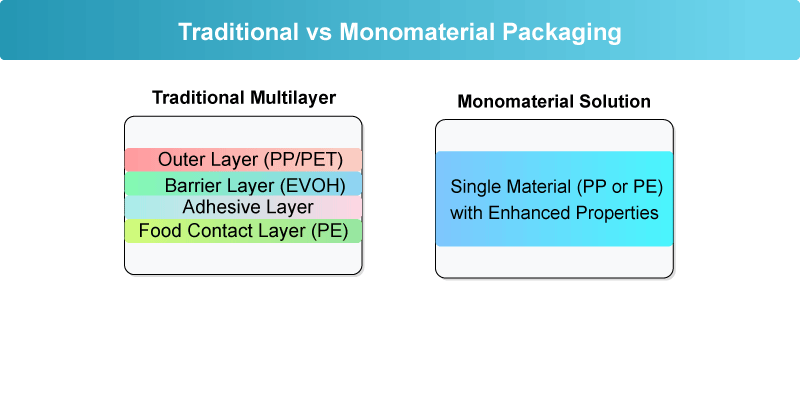

Monomaterials are packaging materials made from a single type of polymer, such as polypropylene (PP) or polyethylene (PE). Unlike traditional multilayer packaging, which combines different materials to achieve specific barrier properties, monomaterials simplify the recycling process by using a homogeneous material.

Why Monomaterials Are Critical to the Future of Sustainable Packaging

1. Reduced Environmental Impact

Traditional packaging often uses multiple layers of different materials, making it challenging to recycle. Monomaterials simplify this process. By using a single type of material, these packages are easier to recycle, contributing to fewer landfill deposits and promoting a circular economy.

2. Enhanced Recycling Rates

The simplicity of monomaterials extends to the recycling stage. A single-material composition allows for more efficient and economically viable recycling processes. This not only lowers the overall cost of recycling but also increases consumer participation, thereby boosting overall recycling rates.

3. Enhanced Product Shelf-Life and Protection

Contrary to what some may believe, monomaterials can offer the same barrier properties as traditional multilayer packaging. Innovations in material science have enabled the development of monomaterials that provide excellent protection against moisture, oxygen, and other contaminants, thus ensuring a longer shelf-life for products.

4. Lower Production Costs

Monomaterials streamline the production process by reducing the complexity involved in combining multiple materials. This simplification can lead to lower manufacturing costs, making sustainable packaging more accessible and cost-effective for businesses.

5. Regulatory Compliance

With increasing global regulations favoring recyclable and reusable materials, monomaterials stand out as a compliant choice. Many regions are tightening their packaging material regulations, and monomaterials align well with these future standards, making them an attractive option for businesses aiming for regulatory compliance.

Bonus: Increased Consumer Trust and Satisfaction

Consumers are increasingly aware of the environmental impact of their purchases. Packaging that is labeled as recyclable and environmentally friendly tends to attract more attention and trust. By using monomaterials, companies can meet consumer demand for sustainability while enhancing their brand image.

The Role of Recycling Systems

For monomaterials to reach their full potential, robust recycling systems are necessary. Here are some types of recycling systems relevant to monomaterials:

Mechanical Recycling

Mechanical recycling involves physically processing the material to produce new products. Monomaterials, being single-composition, are highly suitable for this method as it simplifies the sorting process.

Chemical Recycling

Chemical recycling breaks down the material at the molecular level to produce new polymers. Monomaterials can be efficiently processed through chemical recycling, offering a sustainable loop for materials that might be hard to recycle mechanically.

Closed-Loop Systems

Closed-loop recycling systems aim to keep materials in use for as long as possible by continually reprocessing them into the same product. Monomaterials fit perfectly into closed-loop systems due to their recyclability, promoting a sustainable life cycle.

Summary

Monomaterials stand at the forefront of flexible packaging sustainability, offering reduced environmental impact, enhanced recycling rates, improved product protection, and lowered production costs. For packaging engineers, understanding and implementing monomaterials can be a powerful step toward future-proofing packaging solutions.

Monomaterials stand at the forefront of flexible packaging sustainability, offering reduced environmental impact, enhanced recycling rates, improved product protection, and lowered production costs. For packaging engineers, understanding and implementing monomaterials can be a powerful step toward future-proofing packaging solutions.

Ready to take your packaging to the next level? Explore Sealstrip’s green solution, VerdeSeal, and discover how we can help you create efficient, compliant, and eco-friendly packaging.

By leveraging the advantages of monomaterials, we can make significant strides in achieving a more sustainable future. Prepare for the future of flexible packaging recycling now!