Lose the Leakers

Don’t Lose Because of Leakers

“Leaker packages are a losing proposition for the entire value chain.”1 When your package experiences seal failures, you’ve got the notorious “Leakers.” Avoiding leakers can save expenses from waste and downtime on the packaging line, returns, distributor and retailer complaints. “Finally, leakers produce losses of consumer loyalty and market share.”1 The cost of a package with significant leaking was 20+% higher than that of a superior package.2 So how can you avoid this package failure with superior packaging?

Where Do Leakers Come From?

Let’s start by defining “Leaker.” Most consumer products stay fresh in packaging by maintaining the film barrier property and reducing exposure to oxygen. MAP (modified atmosphere packaging), vacuum packaging and HPP (high pressure packaging) provide part of the solution3 – but if seal integrity is compromised, the barrier is negated, and oxygen and moisture enter through channel leakers.

Seal Temperature Variance

One major reason for seal compromises in flexible packaging is seal temperature variance. As many operators know, seal temperatures vary on packaging equipment and vary by line speeds increasing or decreasing as they are apt to do in production. Too low and the seal strength is diminished, increasing leakers. Too high and film can distort or tear. When making resealable flexible packages the addition of zipper magnifies the problems by drastically changing the need for consistent seal temperatures.

Additional Structural Thickness

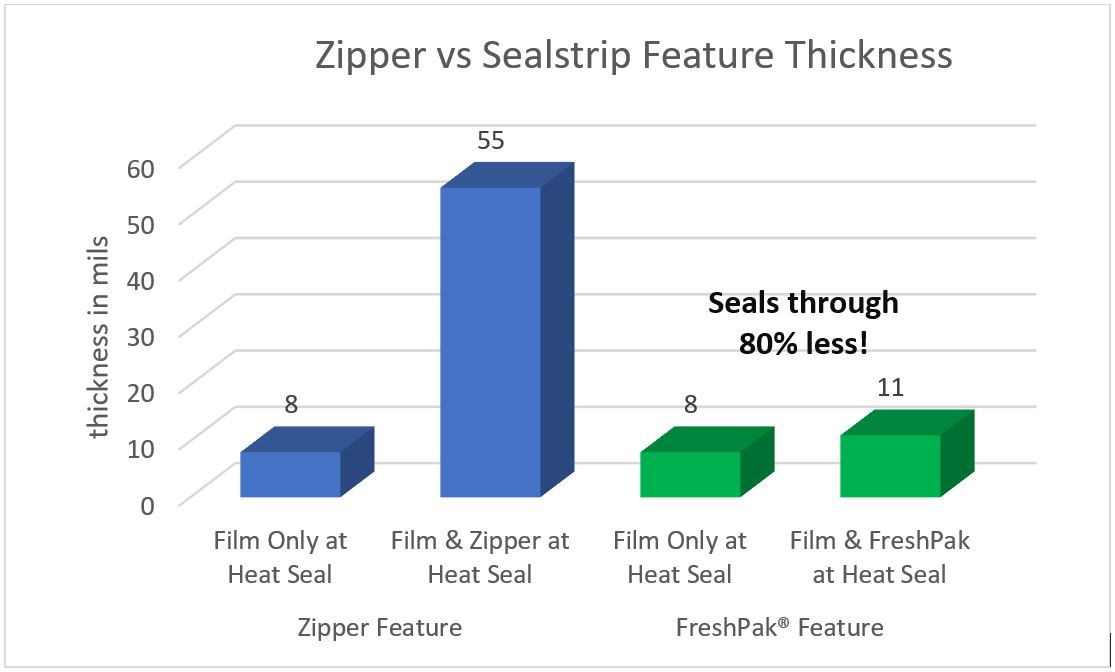

Another key factor in seal integrity is sealing through added structural thickness. It’s no secret consumers want resealable packaging, but we’re guessing they don’t know the headaches Operations experiences in adding zipper resealable features to flexible packages. Our customers tell us 80% of leakers come from the zipper area. The thicker the materials through which a seal bar must successfully seal, the greater the chance of seal failure and leakers. (See chart below.)

How Can You Eliminate Leakers in Convenience Packaging?

Sealstrip easy open and resealable features have significantly less structural thickness through which to seal, eliminating the two leading causes of leakers in zipper convenience packaging. Sealstrip’s FreshPak® requires a heat seal to go through 80% less total material thickness than a standard zipper, so the seal integrity is maintained consistently. Additionally, seal temperature variance affects zipper negatively as in packs with wrinkles and channels - a sealant must first flow into and caulk potential channel leakers.4 Sealstrip features are significantly thinner and rarely affected by seal jaw temperature variance.

Sometimes easy open is all that is needed for a single-use package, but hermetic sealing and food safety are still concerning issues. Sealstrip thin pressure sensitive Teartapes are offered in direct food contact and maintain hermetic seals to avoid causing leakers.

Sealstrip applicators are easily retrofit to existing machinery, reduce operational downtime, run at line speeds, and take up little to no floor space. Sealstrip materials are also a seamless integration, provided in a number of FDA compliance levels, and deliver hours of continuous operation between roll changes.

Win on the Line and In the Hands of Consumers

Sealstrip features don’t just make Operation’s day easier. We’re saving money lost due to package failures from the plant, to the distributor, retailer, and ultimately the consumer. Brand enhancement should come with increased brand loyalty; a Sealstrip reseal feature wins on the line and in the hands of consumers because your packaging is convenient and your product stays fresh and protected!

Lose the Leakers with Sealstrip easy open and resealable features for flexible packaging! Maintain efficiency in your production line and enhance consumer experiences! Contact us and we’ll discuss your opportunities and send you free samples!

With over 40 years of engineering innovative solutions, Sealstrip Corporation provides flexible packagers with the resealable and easy open packaging solutions that are essential to compete in today’s consumer market. The company designs and manufactures applicators that retrofit to customers’ existing wrapping machinery. Sealstrip also manufactures the pressure-sensitive tapes used to form the easy open and resealable features on flexible packages. Although Sealstrip distributes worldwide, products are designed and made in the USA.

Research and statistics from DuPont Packaging, PolyPrint Inc. and Sealstrip Corpoation.

1,2 DuPont Packaging, Morris, Barry. "Sure Ways to Reduce Package Sealing Failure." http://www2.dupont.com/Packaging_Resins/en_US/assets/downloads/white_papers/Reduce_Package_Sealing_Failure_Barry_Morris_November_2010.pdf 2010, , pp. 1

3,4 PolyPrint Inc. "Oxygen Transmission Rate." http://www.polyprint.com/flexographic-otr.htm