Peel&Seal

Award-Winning Peel&Seal® is the most cost effective, consumer friendly reseal on the market.

Consumers love Peel&Seal because it is easy to use, space efficient and keeps the product fresh. After opening the package by the current method, the consumer reseals the package by peeling the Peel&Seal tape away from the top of the bag, rolling the bag closed and sealing it down with the tape. As the product is used, the package rolls down further, resulting in a bag with less air, resealing with fresh tape, keeping the product fresh longer with a more compact bag for storage, and providing a visual trigger to buy more!

You’ll love Peel&Seal because the simple, easy to maintain retrofit applicator and pressure sensitive tapes are the most cost effective, run at your line speed on vertical baggers or horizontal wrappers, and require no additional packaging film!

Patented in the USA and Canada.

Perfect for:

- Refrigerated and Frozen Foods

- Candy and Snacks

- Shelf Stable Foods

- Salads, Fresh Produce

Peel&Seal Applicators

The Peel&Seal® applicator unwind system retrofits to new or existing vertical form-fill-seal baggers. The applicator operates at your current line speed and applies the Peel&Seal material continuously in the film flow direction.

The Peel&Seal material is applied at the center area of the package, front or back, end seal to end seal, parallel to the linear side of the package.

The Peel&Seal applicator utilizes a smooth simple rotary unwind adding packaging efficiency, durability and consistency to your production line.

The Peel&Seal applicator is about the size of a microwave oven and can easily be mounted in minimal space areas.

Peel&Seal Stand Applicator

The Peel&Seal® Stand Applicator applies the reseal feature on a vertical bagger without a custom mounting. Low cost, simple setup available for quick shipment.

Peel&Seal Tabletop Applicator

The Peel&Seal® table top dispenser provides the quick and easy manual application of the Peel&Seal tape. The Peel&Seal applicator utilizes a smooth rotary unwind and an easy to use tape cut off system. The cut off piece of tape is then applied to a bag or a package. Peel&Seal tape provides the consumer with a consistent and reliable reclosable feature.

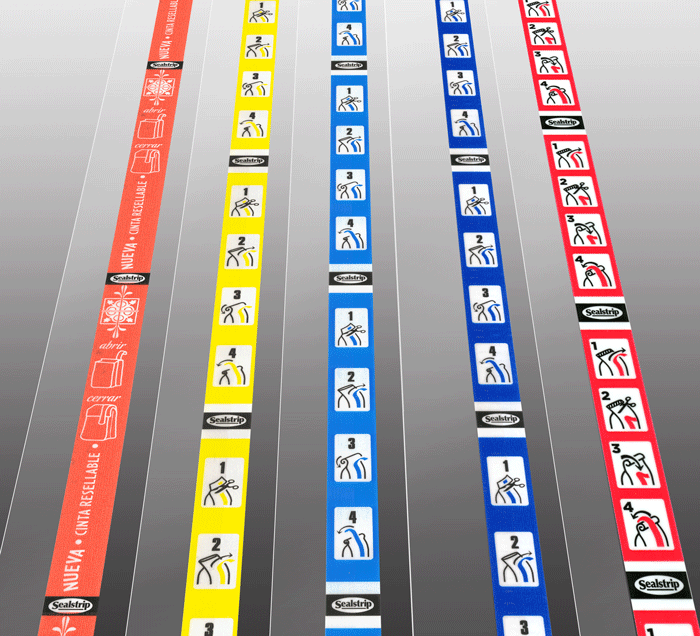

The Peel&Seal tape graphics provide consumer usage directions.

Peel&Seal is typically used as an easy reclose feature for a diverse range of products including: confectionary, bakery, fresh cut produce, dry beans, rice and sugar, and snack foods.

Resealable Package Usage

To use the package, the consumer peels back the printed film edge of the tape, rolls the bag closed, and uses the tape to securely seal the rolled bag closed. As the product is used, the package rolls down further, resulting in a bag with less air, keeping the product fresh longer with a more compact bag for storage.

Patented in Canada and the USA.

Peel&Seal Materials

Peel&Seal material is a pressure sensitive tape with a linear non-adhesive printed grip edge. Standard widths are 1″ (25mm) and 1.25″ (32mm). The long length rolls provide extended run times. Along with being freezer compatible, and moisture resistant, Peel&Seal is FDA compliant and is compatible with a wide variety of film structures.

Peel&Seal material is a pressure sensitive tape with a linear non-adhesive printed grip edge. Standard widths are 1″ (25mm) and 1.25″ (32mm). The long length rolls provide extended run times. Along with being freezer compatible, and moisture resistant, Peel&Seal is FDA compliant and is compatible with a wide variety of film structures.

The tape comes in a standard red and black instructional print and can also be customized with branded graphics and optimized width.

Peel&Seal is a cost effective alternative to traditional reclosable features such as zipper packaging or tin ties.

Peel&Seal is patented in the USA and Canada.

NOW Available as Recycle-Ready Material Available!

Call 1-888-658-7997 for purchase orders or more information about the Peel&Seal system.