If I Hear Sustainability One More Time

If I Hear ‘Sustainability’ One More Time…

Don’t even say it. Can’t afford to. Don’t know how to. Can’t. Don’t. Won’t.

We understand. It is on the list of consumer desires, but they don’t want to pay for it, and neither do you. But what if we told you there are a few very easy, cost effective, and proven methods to deliver a more sustainable package?

Light-Weighting

The best news is, if you’re using flexible packaging, your package and production floor are probably already on their way to being sustainable. Contrary to popular belief, the environmental cost of plastics in consumer goods is roughly a quarter of the cost of alternatives ($139 billion vs $533 billion1, to be exact). That’s a HUGE difference.

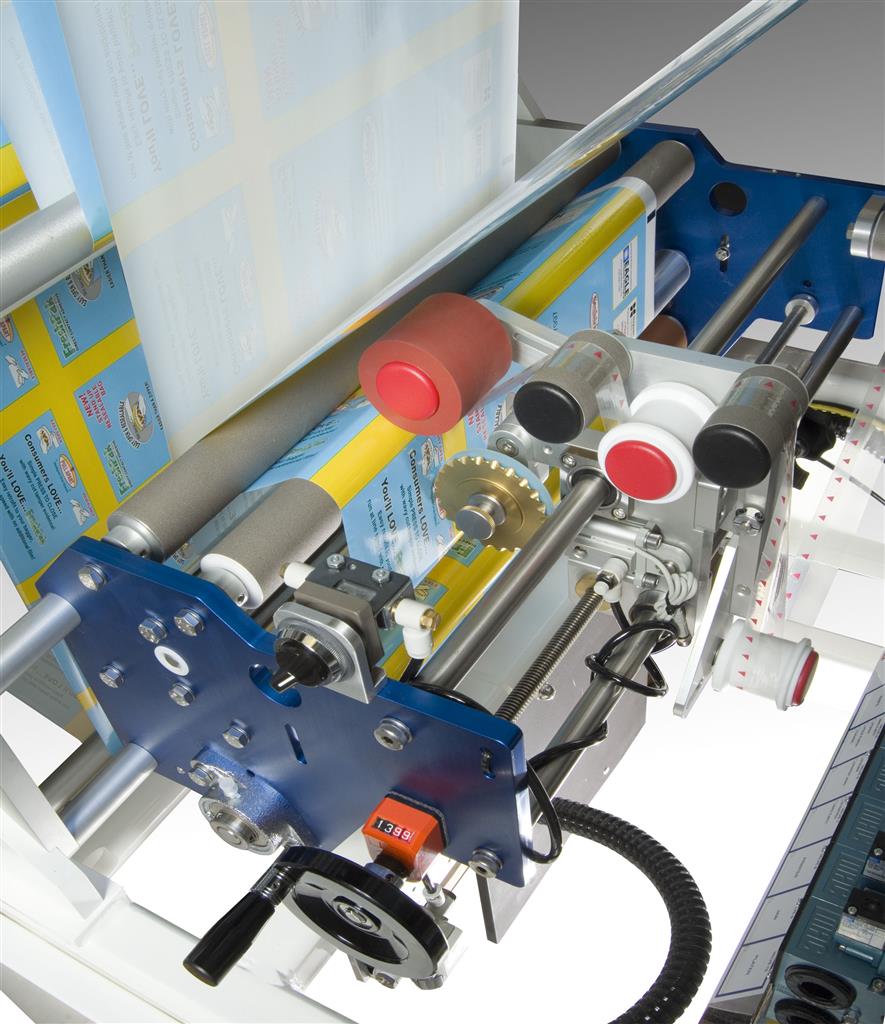

Flexible packaging can improve sustainability even further by light-weighting. Reduce the thickness and layers in your packaging film. Don’t be concerned about losing functionality, Sealstrip easy open and resealable features are designed

to use less film and energy in production, while providing superior convenience.

“Primary, secondary, and tertiary packaging represents only 10 percent of the cumulative energy demand associated with producing food for consumption.” 2 And this refers to all forms of packaging. Prior to consumer usage, flexible packaging takes less energy, generates less emissions, requires fewer trucks to transport (less fuel, less emissions), and reduces spoilage and waste.3

Maintain Freshness

The environmental and economic cost spans from production to the landfill. 80% of food waste happens at the consumer level 4 – and you might say, “Well, that’s not my problem!” Turns out, “10-15 percent of revenue is lost due to spoilage, age dating, package damage and mark downs.” 5 That’s money that could have been in your pocket!

“Discarded food wastes not only the food, but the resources to produce, transport, package and store food.” 6 Interestingly, two thirds of food waste comes from storage! But how can an engineer, marketer, or brand owner help what consumers throw away? Well, we can’t be in the homes of every consumer, but our packaging is!

“10-15 percent of revenue is lost due to spoilage, age dating, package damage and mark downs.”

By utilizing packaging that improves shelf life, gets all of the product out, and protects that product from damage and spoilage, you can improve overall sustainability and reduce product waste. Sealstrip features provide easy open for full access to the product, resealable to maintain freshness and taste, and unique tamper evidence. Our convenience features maintain the packaging barrier, hermeticity and do not compromise oxygen and water vapor transmission rates.

It is estimated that “a conservative 20-25% of household food waste could be reduced through optimized packaging.” 7

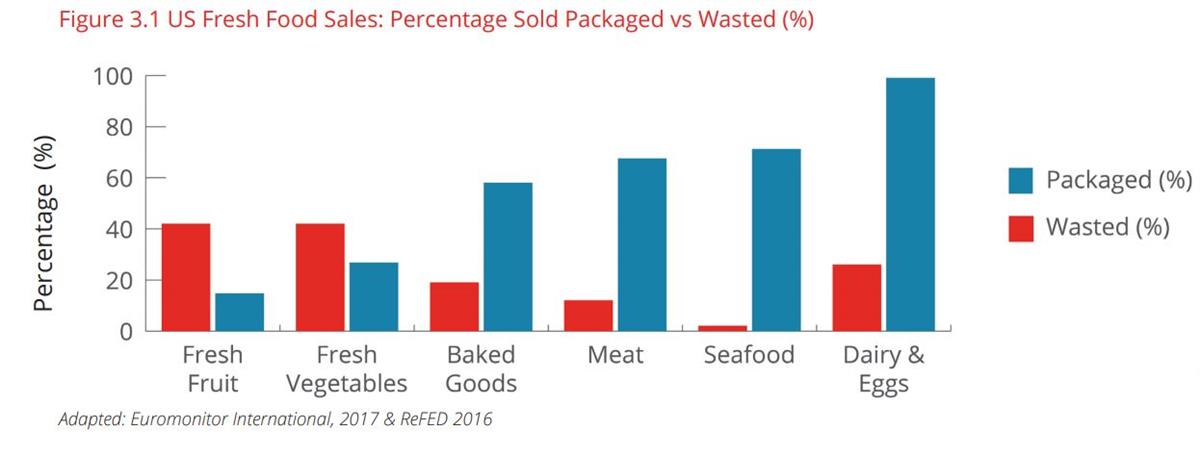

Package What Previously Wasn’t Packaged

Foods with the highest percentage of waste also have the least amount of packaging. The life of a squash can go from 1 day with no packaging to 5 days with packaging.8 Similarly, the squash’s greenhouse gas emission ratio of food to packaging is 178:1.9 There are several examples across the food industry with similar results.

You might argue that consumers have a number of opportunities to be greener, such as composting. “Preventing food waste in the first place results in 6 times greater greenhouse gas emissions savings than composting.” 10 Preventing food waste could decrease food costs by up to 20 percent.11,12

Sealstrip easy open and resealable features (and retrofit applicators) are ideal for shrink and non-shrink packaging on baked goods, snacks, frozen/refrigerated foods, meats & cheeses, candy, shelf-stable foods, and fresh produce, to name a few. The transition to flexible packaging and convenience is headache-free, FDA compliant, and cost-effective. Not to mention, the boost in revenue:

“The median monetary benefit that businesses captured through food waste reduction initiatives, including improved packaging, produces a 14-to-1 return on investment. Every $1 results in a benefit of $14 over a five-year period.”

“A one percent reduction in food waste can translate to the equivalent of a four percent increase in revenue. Consumers pay for avoidable food waste in the form of 10 percent or more of prices paid…the investment in changing production lines to extend the shelf life of foods typically pays off in two to three years. The median monetary benefit that businesses captured through food waste reduction initiatives, including improved packaging, produces a 14-to-1 return on investment. Every $1 results in a benefit of $14 over a five-year period.” 13,14,15

Wrap It Up

Utilizing light-weighting, maintaining freshness and introducing packaging where there was none are smart and cost effective ways to not only create a sustainable product, but earn extra revenue. But let’s not forget how pertinent it is to market your newfound or improved sustainability!

Utilizing light-weighting, maintaining freshness and introducing packaging where there was none are smart and cost effective ways to not only create a sustainable product, but earn extra revenue. But let’s not forget how pertinent it is to market your newfound or improved sustainability!

“When presented with information on the value of packaging in reducing food waste almost a quarter of consumers will shift their purchasing decisions towards the package promoting extended value.” 16

Promote your sustainability and convenience benefits through package graphics, advertising, and usage videos (YouTube is free, and every one of you has a smart phone!).

Sealstrip easy open and resealable features for flexible packaging can improve your consumers’ experiences and help you to create sustainability in your production line! Contact us and we’ll discuss your opportunities and send you free samples!

Sealstrip is a proud supporter of Feeding America. The issue of food waste is important when 1 out of every 8 Americans are food insecure. Learn more here.

With over 40 years of engineering innovative solutions, Sealstrip Corporation provides flexible packagers with the resealable and easy open packaging solutions that are essential to compete in today’s consumer market. The company designs and manufactures applicators that retrofit to customers’ existing wrapping machinery. Sealstrip also manufactures the pressure-sensitive tapes used to form the easy open and resealable features on flexible packages. Although Sealstrip distributes worldwide, products are designed and made in the USA.

- American Chemistry Council (2016) “Ocean Damage, End of Life Management, Transport, Production, Materials Energy and Recovery”

- INCPEN (2009) “Table for One”

- Flexible Packaging Association (2018) “State of the Industry”

- ReFED (2016) “A Roadmap to Reduce U.S. Food Waste by 20 Percent”

- BSR “Food Waste Tier 1 Assessment” for GMA/FMI

- INCPEN (2009) “Table for One”

- Buzby, Jean, Hodan F Wells & Jeffrey Hyman (2014) “The Estimated Amount, Value and Calories of Postharvest Food Losses at the Retail and Consumer Levels in the United States” USDA Economic Research Service Economic Information Bulletin No EIB-121

- Flexible Packaging Association (2018) “State of the Industry”

- Sealed Air (2017) “Internal Life Cycle Study”

- NRDC (2017) “Wasted”

- Gooch, M., Dent, B., Felfel, A.S., Vanclief, L., Whitehead, P. (2016) “Food Waste: Aligning Government and Industry Within Value Chain Solutions”

- Value Chain International RMIF (2002) “Cutting Costs—Adding Value in Red Meat” Red Meat Industry Forum; Food Chain Center, Institute of Grocery Distribution.

- ReFED (2016) “A Roadmap to Reduce U.S. Food Waste by 20 Percent.”

- Gooch, M., Dent, B., Felfel, A.S., Vanclief, L., Whitehead, P. (2016) “Food Waste: Aligning Government and Industry Within Value Chain Solutions”. Value Chain Management International.

- Hanson C. & Mitchell P. (2017) The Business Case for Reducing Food Loss and Waste. Champions 12.3

- Sealed Air (2015) “Taking Stock: Retail Shrink Solutions”